R&D at infoteam: We actively shape the future.

Our pursuit of excellence extends to all facets of our work, with research and development (R&D) playing a central role in our mission. In a rapidly evolving world, we place particular emphasis on being at the forefront of technological advances. Our expertise and passion for innovation is manifested in our dedicated participation in pioneering research projects. One outstanding example is the 'RoboFill' project, in which we developed the foundations for our iAgent (artificial intelligence) multi-agent system.

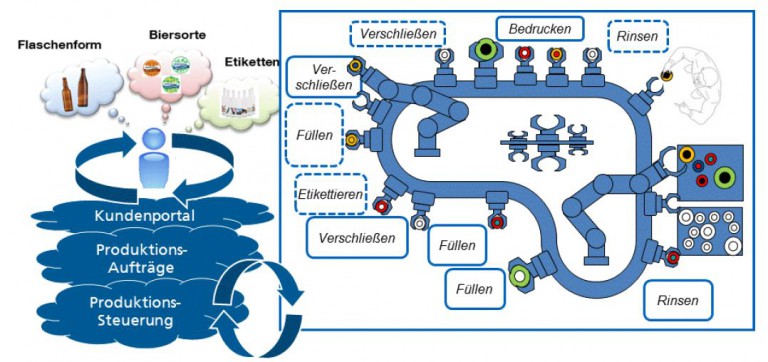

Robot-assisted filling concept for individualized beverage supply - RoboFill 4.0

© Technical University of Munich; Schematic representation of the targeted filling concept for the individualized provision of bottled beverages using Industry 4.0 methods.

The RoboFill research project was carried out by the Technical University of Munich, infoteam Software AG and other renowned partners between 2016 and 2019. The aim of the project was to develop a flexible and modularly expandable filling system for the industrial provision of personalized and customized beverages in very small quantities.

The system is based on a cyber-physical system in which the physical system is linked to a digital twin. This enables autonomous and individual control of the system, which adapts to the customer's wishes.

infoteam Software AG has made the following contributions to the project:

- Development of the iAgent multi-agent system (field of artificial intelligence)

- Development of the software platform for the decentralized control of the system: This software enables the individual components of the system to communicate with each other and exchange information. This is important for the flexible and modular expansion of the system.

- Development of the software for recording and processing sensor data: This software records the properties of the beverages and the bottles. This information is important for generating the filling strategy.

- Development of the software for generating the filling strategy: This software generates the filling strategy for each individual bottle. This strategy takes into account the customer's individual wishes.

Projektpartner

Technische Universität München (Projektleitung), Bayerische Staatsbrauerei Weihenstephan, Beckhoff Automation GmbH, Dekron GmbH, Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik, Krones AG, Proleit AG, Siemens AG, Technische Universität München, Wissenschaftszentrum Weihenstephan für Ernährung, Landnutzung und Umwelt, Yaskawa Europe GmbH, Zimmer GmbH

Das Forschungsprojekt RoboFill hat gezeigt, dass es möglich ist, eine flexible und modular erweiterbare Abfüllanlage zu entwickeln, die die Anforderungen der individualisierten Getränkeproduktion erfüllt. Die Anlage ist für eine Vielzahl von Getränken und Flaschentypen geeignet und kann auch für die Losgröße 1 eingesetzt werden.

Das Forschungsprojekt RoboFill wurde erfolgreich abgeschlossen. Die Abfüllanlage wurde in der Forschungsbrauerei der TU München installiert und getestet. Die Anlage ist in der Lage, Getränke mit individuellen Geschmacksrichtungen, Zutaten oder Verpackungen in kleinster Auflage herzustellen.

Mögliche Anwendungen:

- Personalisierte Getränke: Die Anlage kann für die Herstellung von Getränken mit individuellen Geschmacksrichtungen, Zutaten oder Verpackungen eingesetzt werden.

- Kleinserienproduktion: Die Anlage kann für die Herstellung von Getränken in kleinen Auflagen, beispielsweise für Events oder Veranstaltungen, eingesetzt werden.

- Nachfrageorientierte Produktion: Die Anlage kann für die Herstellung von Getränken nach Kundenwunsch eingesetzt werden.

Ausblick:

Das Forschungsprojekt RoboFill ist ein wichtiger Schritt zur Realisierung der individualisierten Getränkeproduktion. Die Anlage hat das Potenzial, die Getränkeindustrie zu revolutionieren und neue Geschäftsmodelle zu ermöglichen.

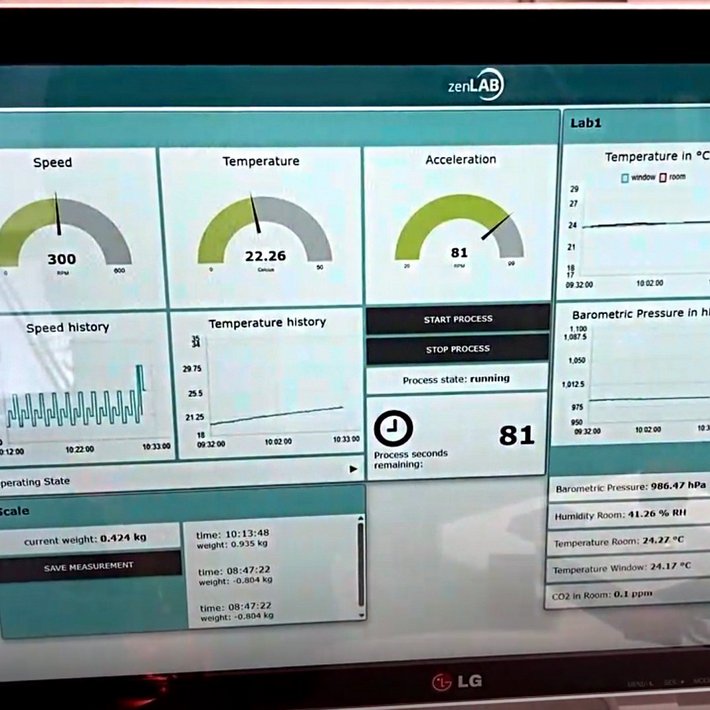

MeLasKo research project

The MeLasKo research project was carried out by the Technical University of Munich (TUM), ERLAS Erlanger Lasertechnik GmbH and infoteam Software AG between 2018 and 2021. The aim of the project was to develop intelligent methods for setting up highly automated laser welding processes.

The project partners were renowned in their respective fields. TUM is one of the leading universities in Germany and has many years of expertise in production automation. ERLAS Erlanger Lasertechnik GmbH is a leading manufacturer of laser cutting and laser welding systems. infoteam Software AG is a renowned software developer with expertise in industrial automation.

As part of the project, various innovative processes were developed to improve the safety and efficiency of laser welding processes. These include:

-

a method for automatically determining the optimum laser parameters

-

method for the automatic detection of welding faults

-

a method for automatically adapting the welding process to changing environmental conditions

infoteam Software AG made the following contributions to the project: -

Development of a software platform for the visualization and analysis of laser welding data

-

Development of an algorithm for the automatic determination of optimal laser parameters

-

Development of an algorithm for the automatic detection of welding errors

D-LEAP research project

© FAPS; D-LEAP – Distributed Machine Learning in Electronics Production

The aim of the D-LEAP research project is to develop intelligent maintenance strategies that meet these requirements. Intelligent maintenance strategies are based on data and algorithms to determine the optimal maintenance timing and measures. This can reduce maintenance costs by avoiding unnecessary maintenance measures. In addition, plant availability can be increased by carrying out maintenance measures in good time.

infoteam Software AG made the following contributions to the project:

- Development of a software platform for the visualization and analysis of maintenance data: This software makes it possible to visualize and analyse maintenance processes in real time. This enables better control and optimization of maintenance.

- Development of algorithms to automatically determine the optimal maintenance strategy: The algorithms developed are based on machine learning and take into account the individual conditions of the systems and production lines.

- Development of algorithms for the automatic execution of maintenance measures: The algorithms developed make it possible to carry out maintenance measures without human intervention.

- Development of a software platform for the visualization and analysis of maintenance data

- Development of algorithms to automatically determine the optimal maintenance strategy

- Development of algorithms for the automatic execution of maintenance measures

E-Mail:

siegfried.schuelein@infoteam.de

Phone:

+49 9131 78 00-316

E-Mail:

michael.bojnec@infoteam.de

Phone:

+49 9131 78 00-142